Vapour Compression Refrigeration

It is the most common method of refrigeration and employed from the smallest household refrigerator to the largest air conditioning plant. It works under the principle that liquid when evaporates absorbs heat from the surroundings, thereby making it cool. In this system, the common refrigerant are Ammonia, Carbon dioxide and Feron.

Once the refrigerants is charged in the system, the same refrigerant is used again and again in the system in a cycle changing from liquid to vapour state when absorbing heat and from vapour to liquid state when giving out heat.

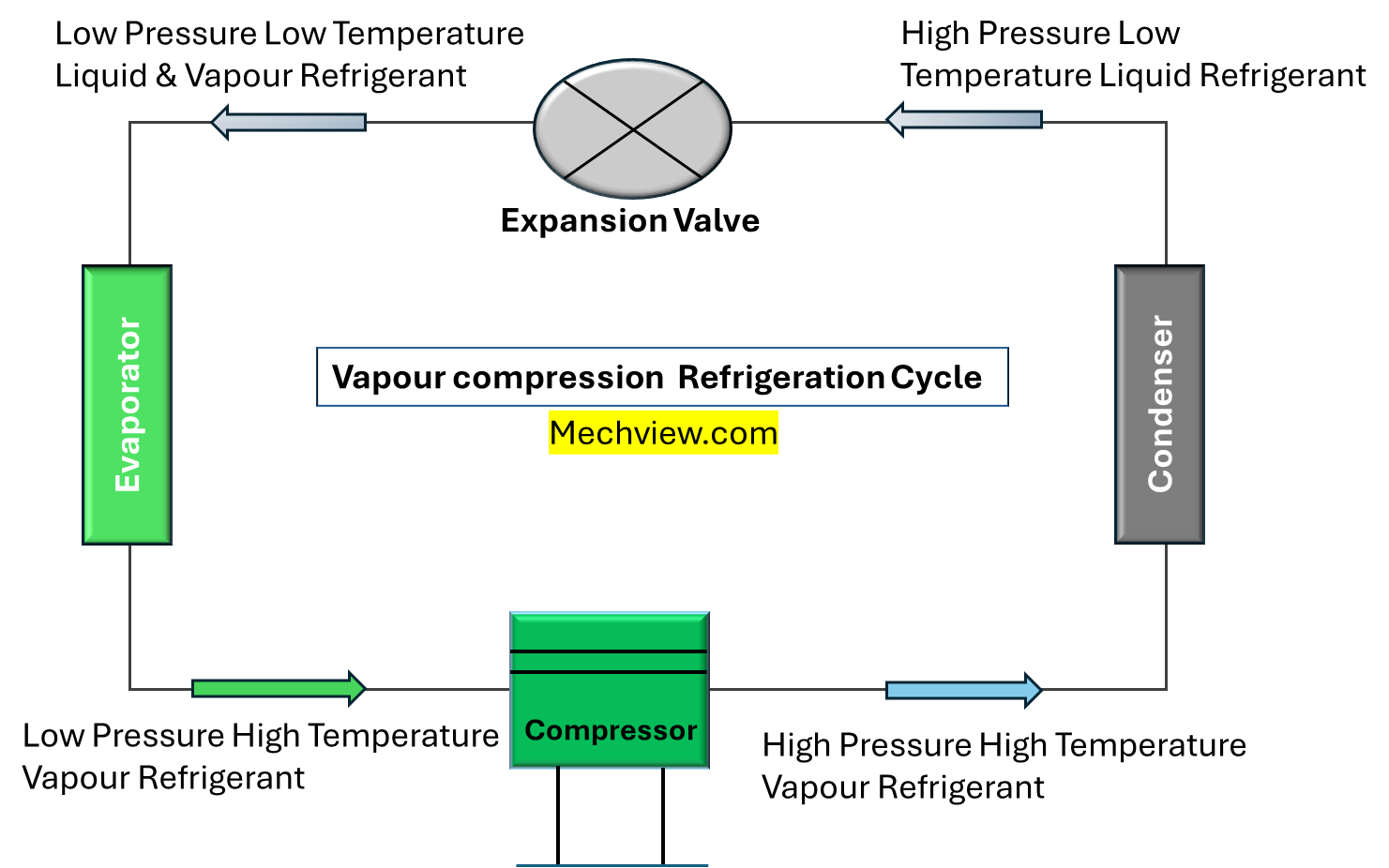

The main components involved in this system are Compressor, Condenser, Expansion valve and Evaporator. The refrigerant absorbs heat from the space to be cooled and rejects it at the condenser i.e. from a lower temperature to higher temperature. This is also named as mechanical refrigeration and is the best system for producing refrigeration.

Working of Vapour Compression Refrigeration:

1. Compression: The process starts with a compressor that compresses a low-pressure refrigerant vapor into a high-pressure, high-temperature gas. This compression increases the energy and temperature of the refrigerant.

2. Condensation: The high-pressure gas then moves into the condenser, where it releases heat to the surroundings. As the refrigerant loses heat, it condenses into a high-pressure liquid.

3. Expansion: The high-pressure liquid refrigerant passes through an expansion valve or capillary tube. This expansion valve reduces the pressure of the refrigerant suddenly, causing it to expand rapidly. As it expands, its temperature and pressure drop significantly.

4. Evaporation: The low-pressure, low-temperature refrigerant then enters the evaporator, which is the part of the system where cooling occurs. In the evaporator, the refrigerant absorbs heat from the surroundings.

5. Return to Compressor: The low-pressure refrigerant vapor returns to the compressor to start the cycle again. This continuous cycle of compression, condensation, expansion, and evaporation maintains the cooling effect in the refrigeration system.

Vapor Absorption Refrigeration System (VARS)

The vapour absorption system is the one of the oldest, simplest and economical method to produce refrigerating effect. This system of refrigeration is used in both the domestic and in large air conditioners installation. The refrigerant, commonly used in a vapour absorption system is ammonia.

This system uses heat energy instead of mechanical energy. In the vapour absorption system, the compressor is replaced by an absorber, a pump, a generator and pressure reducing valve. These component in vapour absorption system perform the same function as that of a compressor in vapour compression system.

There are different combinations used in different absorption refrigeration systems. Some of the combinations used in absorption refrigeration systems are given below:

- Ammonia as refrigerant and water as absorbent.

- Water as refrigerant and lithium bromide as absorbent.

- Sulphur dioxide as refrigerant and silica get as absorbent.

Working of Vapour Compression Refrigeration:

Evaporation: The refrigerant (water) evaporates in the evaporator, absorbing heat from the surroundings and creating a cooling effect.

Absorption: The vaporized refrigerant then enters the absorber, where it combines with the absorbent (lithium bromide), forming a concentrated solution. The solution is pumped with the help of pump, to generator where it is heated.

Generation: The concentrated solution is heated in the generator using a heat source (like steam or natural gas or Solar system). This causes the refrigerant to separate from the absorbent as vapor.

Condensation: The refrigerant vapor is then condensed back into liquid form in the condenser, releasing heat to the surroundings and completing the cycle.

Recovery and Recirculation: After condensation, the liquid refrigerant is often collected and recirculated back to the evaporator, while the absorbent solution is returned to the absorber for reuse. This continuous cycle allows the Vapour Absorption Refrigeration System to maintain its cooling effect without the need for a mechanical compressor.

Vapor Compression vs. Vapor Absorption Refrigeration

| Aspect | Vapour Compression Refrigeration (VCR) Cycle | Vapour Absorption Refrigeration (VAR) Cycle |

|---|---|---|

| Components | The main parts like, compressor, condenser, expansion valve and evaporator and used. | The main parts like generator, condenser, evaporator and absorber are used. |

| Energy Source | Electric motor for compressor | Waste heat, solar energy, or other low-grade sources |

| Efficiency | Generally higher | Lower, especially in small-scale applications |

| Chances of Leakage | Chances of Leakage of refrigerant are more. | Chances of Leakage of refrigerant is nil. |

| Applications | Air conditioning, refrigeration, heat pumps | Large-scale refrigeration, industrial cooling |

| Complexity and Cost | Simpler design, lower initial cost | More complex, higher initial cost and maintenance |

| Flexibility | Limited energy source options | Can utilize waste heat effectively |

| Cooling Capacity | Typically, higher | Lower in comparison to VCR cycle |

| Size of Installation | Smaller footprint, suitable for various settings | Larger footprint, more suited for industrial and large-scale use |

| Refrigerant charging | In VCR system, charging of refrigerant is simple. | In VAR system, charging of refrigerant is difficult. |

| Pipe used to connect parts | Generally copper pipe is used to connect parts. | Steel pipe is used to connect parts. |

| Maintenance | Generally easier and less frequent | More complex maintenance due to additional components |

| Efficiency vs. Load | Efficiency can vary with load conditions | More stable efficiency across varying loads |

| Environmental Concerns | Concerns about synthetic refrigerants and their impact | Potential for using eco-friendly refrigerants and energy sources |

| Operational Flexibility | Limited by electricity availability | Can operate using waste heat, solar energy, or other sources |

| Technology Advancements | Continual improvements in efficiency and design | Advancements in utilizing waste heat and eco-friendly technologies |

| Adoption in Industries | Widely adopted in residential and commercial settings | More prevalent in specific industries and large-scale applications |

| System | It is noisy Refrigeration system. | It is noiseless Refrigeration system. |