Properties of materials:

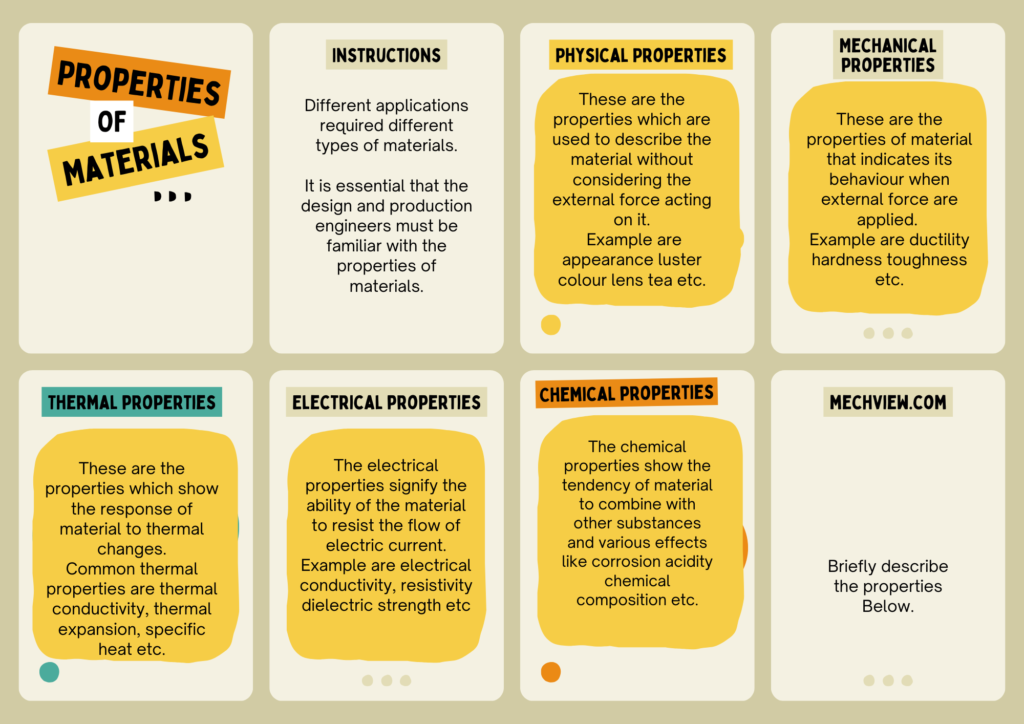

Different engineering application require different type of materials. It is essential that the design and production engineers must be familiar with the properties of materials. In order to design and manufacture component and structures and to avoid failure during use knowledge of the properties of material is desired. Metals and alloys have various physical, chemical, mechanical, electrical and other properties.

The important properties of engineering materials are as the following:

- Physical properties: These are the properties which are used to describe the material without considering the external forces acting on it. These are generally the properties described in the field of physics of materials. The various physical properties are appearance, luster, colour, entity melting point dimensions and structure of material.

- Mechanical properties: The mechanical properties are the characteristic of a material that indicates its behaviour when external forces are applied. The important mechanical properties are strength, electricity, ductility malleability, elasticity, hardness, brittleness, Plasticity and toughness etc.

- Thermal properties: Thermal properties are the properties which show the response of material to thermal changes. Thermal properties are thermal conductivity, thermal expansion, specific heat and heat capacity etc. These properties should be specially considered while making oven, boiler parts which have two withstand high temperature.

- Electrical properties: The electrical properties are the properties which shows the ability of the material to resist the flow of electric current. They include electrical conductivity resistivity dielectric strength superconductivity etc.

- Chemical properties: Chemical properties are the properties which sow the tendency of the material to combine with other substances and various effects like corrosion, acidity, alkalinity, and chemical composition etc.

1. Physical properties of engineering materials:

- Appearance: Due to this property every material have different look. Every metal looks clearly different from other. For Example, aluminium is a silvery white and copper is brownish red. Appearance all metal is totally different from non-metals such as wood stone etc.

- Luster: It is the property of metal to reflect the light due to which the surface of metal shines. the surface of metal looks brighter due to this property.

- Colour: It is the property of appearance of metal, the colour of different metal is very helpful in the metal identification such as aluminium is silvery white, gold is yellow, and copper is reddish brown.

- Density: It is the property of material which helps in differentiating the light material from heavy material. It is defined as the mass occupied per unit volume of that material.

- Porosity: It is the property of the material it has pores within its structure these pores can absorb lubricant which is useful in manufacturing of bearing material.

2. Mechanical properties of engineering materials:

- Elasticity: It is the property of material by virtue of which material changes its shape when load is applied over it but comes back into its original shape when the load is removed known as elasticity. It may be noted that steel is more elastic than rubber.

- Plasticity: It is the property of material due to which it can be converted into a desired shape.

- Malleability: It is the property of material by virtue of which it can be beaten into sheets, is called malleability.

- Ductility: It is the property of a material by virtue of which it can be drawn into wire by the application of tensile forces.

- Toughness: It is the property due to which metal is able to withstand bending or torsion under high stress before rupture. Toughness is decreases when material is heated.

- Hardness: It is the property of material which resist surface penetration is called hardness of material.

- Strength: Strength may be defined as the property of material by virtue of which it can withstand external force without deformation.

- Machinability: It is the property of a material by virtue of which it can be easily cut to produce a desired shape and size.

- Creep: When a part is subjected to a constant stress at high temperature for a long time it undergoes a slow and permanent deformation the phenomena is called creep.

- Fatigue: When a material is subjected to repeated stresses, it fails at stresses below yield point stresses. Such type of failure of a material is called fatigue.

3. Thermal properties of engineering materials:

- Thermal Conductivity: This property measures how well a material conducts heat. High thermal conductivity means the material can transfer heat quickly, while low conductivity implies slower heat transfer. Metals like copper and aluminum have high thermal conductivity and are used in heat sinks and cooking utensils.

- Thermal Expansion: Materials expand or contract when exposed to temperature changes. The coefficient of thermal expansion (CTE) quantifies this behavior. Understanding a material’s CTE is essential in designing structures to accommodate thermal expansion without causing damage or deformation.

- Specific Heat Capacity: Specific heat capacity is the amount of heat required to raise the temperature of a unit mass of a material by one degree Celsius. Materials with high specific heat capacity can absorb more heat before their temperature increases significantly. Water, for example, has a high specific heat capacity, making it useful for heat storage and regulation.

- Thermal Diffusivity: Thermal diffusivity combines thermal conductivity and density to measure how quickly heat spreads through a material. High thermal diffusivity indicates rapid heat propagation, while low diffusivity means slower heat transfer.

- Melting Point and Boiling Point: These are the temperatures at which a solid material melts to become a liquid and a liquid material boils to become a gas, respectively. These points are crucial in material processing, such as casting, welding, and heat treatments.

- Heat Capacity: Heat capacity is the amount of heat required to change the temperature of a material by a certain amount. It is related to specific heat capacity but considers the mass of the entire object rather than just a unit mass.

- Thermal Resistance: Thermal resistance measures a material’s ability to resist heat flow. It is the reciprocal of thermal conductivity and is used in thermal insulation materials to prevent heat transfer.

4. Electrical properties of engineering materials:

- Electrical Conductivity: Electrical conductivity is the ability of a material to conduct electric current. Metals like copper, silver, and aluminum are good conductors due to their free-flowing electrons, allowing electricity to pass through easily. Conductivity is measured in siemens per meter (S/m) or ohm-meters (Ω·m).

- Resistivity: Resistivity is the inverse of conductivity and measures how much a material resists the flow of electric current. It is denoted by the symbol ρ (rho) and is measured in ohm-meters (Ω·m). Materials with high resistivity are insulators, while those with low resistivity are conductors.

- Dielectric Constant: The dielectric constant (ε) measures a material’s ability to store electrical energy when subjected to an electric field. It is crucial in capacitor design and is used to calculate the capacitance of a capacitor. Materials with high dielectric constants are used as dielectric materials in capacitors.

- Dielectric Strength: Dielectric strength is the maximum electric field strength a material can withstand without electrical breakdown, leading to the formation of an electrical arc or spark. It is an important consideration in insulating materials to prevent short circuits and electrical failures.

- Permittivity: Permittivity is a measure of a material’s ability to permit the flow of electric field lines. It is related to the dielectric constant and is denoted by the symbol ε₀ (epsilon zero) for vacuum or free space. Permittivity influences the capacitance of capacitors and the behavior of electromagnetic waves in materials.

- Conductivity Type: Materials can exhibit different conductivity types based on the movement of charge carriers (electrons or holes). Common conductivity types include:

- Conductors: Materials with high electrical conductivity due to abundant free electrons (e.g., metals).

- Semiconductors: Materials with intermediate conductivity that can be controlled by doping or applying electric fields (e.g., silicon, germanium).

- Insulators: Materials with low conductivity, preventing the flow of electric current (e.g., glass, plastic).

- Superconductivity: Superconductivity may be defined as the state of material in which it has zero resistivity. Resistivity of all metal increase with the temperature.

5. Chemical properties of engineering materials:

Chemical properties of materials refer to how they interact with other substances and undergo chemical reactions. These properties are crucial in various industries such as manufacturing, pharmaceuticals, and materials science. Here are the key chemical properties of materials:

- Chemical Stability: This property refers to a material’s ability to resist chemical reactions and decomposition under specific conditions. Stable materials are less likely to corrode, degrade, or react with other substances.

- Corrosion Resistance: Corrosion resistance is the ability of a material to withstand corrosion, which is the deterioration of a material due to chemical reactions with its environment. Materials like stainless steel and certain polymers are known for their high corrosion resistance.

- Chemical Reactivity: Chemical reactivity describes how readily a material reacts with other substances to form new compounds. Some materials are highly reactive and undergo rapid chemical reactions, while others are more inert and stable.

- Acid and Base Resistance: Materials may exhibit different levels of resistance to acids and bases. Acid-resistant materials are used in environments with acidic substances, while base-resistant materials are suitable for alkaline environments.

- Compatibility: Compatibility refers to how well a material interacts with other substances without causing adverse effects or chemical reactions. For example, materials used in medical implants must be biocompatible to avoid tissue rejection or toxic reactions.

- Solubility: Solubility is the ability of a material to dissolve in a solvent to form a homogeneous mixture. It is important in applications such as drug formulation, chemical processes, and material synthesis.

- Oxidation Resistance: Oxidation resistance is the ability of a material to resist oxidation, which involves the loss of electrons and the formation of oxides. Materials with high oxidation resistance are used in high-temperature applications and environments with oxygen exposure.

- Flammability: Flammability refers to a material’s tendency to ignite and burn in the presence of a flame or heat source. Some materials are highly flammable, while others are flame-retardant or non-combustible.

- Toxicity: Toxicity is the degree to which a material can cause harm or toxicity to living organisms. Materials used in consumer products, food packaging, and medical devices must undergo testing to ensure they meet safety standards regarding toxicity.