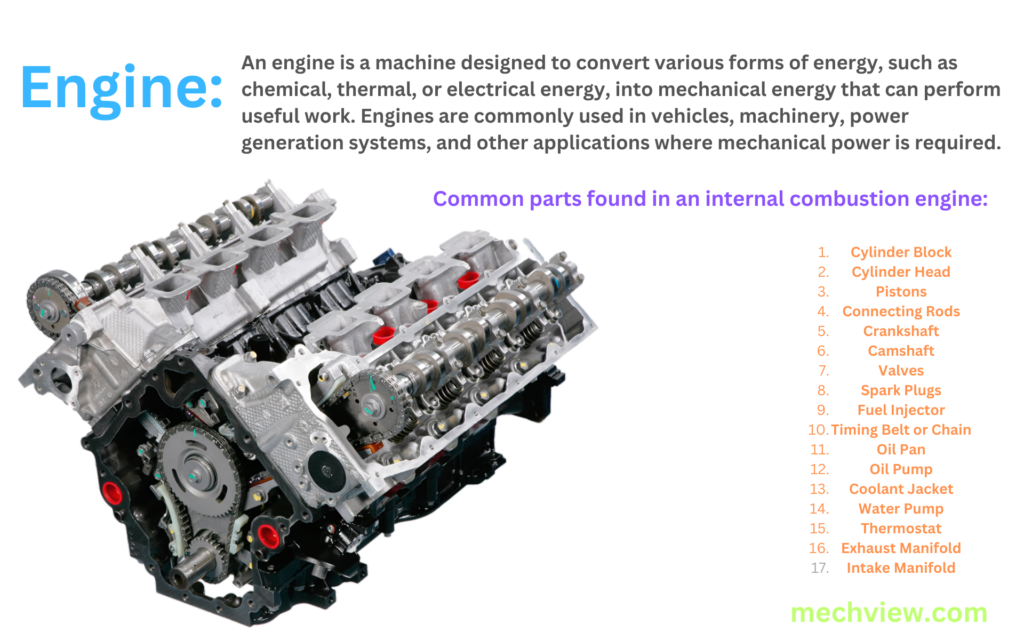

Engine:

An engine is a mechanical device or machine that converts various forms of energy, such as chemical, thermal, or electrical energy, into mechanical energy that can perform useful work. Engines are commonly used in vehicles, machinery, power generation systems, and other applications where mechanical power is required. They play a vital role in powering various mechanical devices and processes by harnessing energy from different sources and converting it into usable mechanical work.

a) External combustion engine: The engine in which the combustion of fuel takes place outside the cylinder is called an external combustion engine. Steam engine and steam turbine are the main example of external combustion engine.

b) Internal combustion engine: The engine in which the combustion of fuel takes place inside the cylinder is called an internal combustion engine. Petrol, oil and gas engines are the general example of internal combustion engine.

Petrol Engine

A petrol engine, also known as a gasoline engine in some regions, is a type of internal combustion engine that operates using petrol (gasoline) as its primary fuel source. Petrol engines are commonly found in automobiles, motorcycles, small boats, lawnmowers, and various power equipment.

Some key characteristics and components of a petrol engine:

- Combustion Process: Petrol engines operate on the four-stroke cycle, which includes intake, compression, power, and exhaust strokes. During the intake stroke, air and fuel (petrol) are drawn into the combustion chamber. The compression stroke compresses this mixture, followed by ignition (via spark plugs) and combustion during the power stroke. Finally, the exhaust stroke expels the burned gases.

- Fuel System: Petrol engines use a fuel injection system or a carburetor to deliver the right air-fuel mixture to the combustion chamber. Modern petrol engines mostly use fuel injection for precise control over fuel delivery and combustion.

- Ignition System: Petrol engines rely on spark plugs to ignite the air-fuel mixture inside the cylinders. The timing of ignition is controlled by the engine’s electronic control unit (ECU) based on various engine parameters.

- Engine Components: A typical petrol engine includes components such as cylinders, pistons, crankshaft, camshaft, valves (intake and exhaust), timing belt or chain, oil system (with oil pump and oil filter), cooling system (radiator, water pump), and exhaust system (including catalytic converter for emission control).

- Performance: Petrol engines are known for their high RPM (revolutions per minute) capability, which allows them to generate more power at higher speeds. They often deliver smoother and quieter operation compared to diesel engines.

- Applications: Petrol engines are widely used in passenger cars, sports cars, motorcycles, small boats, and light-duty vehicles. They are preferred for their smoother operation, quick acceleration, and responsiveness, making them suitable for urban driving and performance-oriented applications.

Diesel Engine

A diesel engine is a type of internal combustion engine that operates using diesel fuel as its primary source of energy. Diesel engines are widely used in various applications, including automobiles, trucks, buses, ships, generators, and heavy machinery. Compared to petrol (gasoline) engines, diesel engines have some distinct characteristics and operating principles:

- Combustion Process: Diesel engines operate on the principle of compression ignition. During the intake stroke, only air is drawn into the combustion chamber. The air is then compressed to a high temperature and pressure during the compression stroke. Diesel fuel is then injected directly into the highly compressed air, where it ignites spontaneously due to the high temperature, without the need for spark plugs.

- Fuel System: Diesel engines use a fuel injection system to deliver precise amounts of diesel fuel into the combustion chamber. Common types of fuel injection systems in diesel engines include direct injection and common rail injection, which allow for efficient and controlled fuel delivery.

- Ignition System: Unlike petrol engines that rely on spark plugs for ignition, diesel engines use compression ignition, where the high temperature and pressure of the compressed air ignite the injected diesel fuel. Diesel engines may use glow plugs during cold starts to preheat the combustion chamber and aid in ignition.

- Engine Components: A typical diesel engine includes components such as cylinders, pistons, crankshaft, camshaft, valves (intake and exhaust), fuel injectors, turbocharger or supercharger (for forced induction), timing belt or chain, oil system (with oil pump and oil filter), cooling system (radiator, water pump), and exhaust system (including diesel particulate filter and selective catalytic reduction system for emissions control).

- Performance: Diesel engines are known for their high torque output at low RPM (revolutions per minute), making them well-suited for heavy-duty applications such as towing, hauling, and long-distance driving. They are also more fuel-efficient than petrol engines due to the higher compression ratios and thermal efficiency.

- Applications: Diesel engines are commonly used in commercial vehicles (trucks, buses), agricultural equipment, construction machinery, marine vessels, power generators, and locomotives. They are preferred for their durability, fuel efficiency, and ability to handle heavy loads and demanding conditions.

Comparison between Petrol Engine and Diesel Engine engine?

| Factor | Petrol Engine | Diesel Engine |

|---|---|---|

| Fuel Type | Uses petrol (gasoline) as fuel | Uses diesel as fuel |

| Cycle | Petrol engine works on otto cycle or constant volume cycle | Diesel engine works on diesel cycle or constant pressure cycle |

| Suction Strock | During suction stroke, the mixture of air and petrol is sucked into the engine cylinder | During suction stroke, only air is sucked into the engine cylinder |

| Combustion Process | Ignites fuel-air mixture with spark plugs | Compresses air to ignite fuel without spark |

| Ignition System | Utilizes spark plugs for ignition | Uses glow plugs for cold starts and compression ignition |

| Fuel Efficiency | Generally lower compared to diesel engines | Typically higher due to higher compression ratio and thermodynamic efficiency |

| Torque | Lower torque at lower RPMs | Higher torque at lower RPMs |

| Compression Ratio | The compression ratio in petrol engine varies from 5:1 to 9:1 | The compression ratio in diesel engine varies from 14:1 to 22:1 |

| Power Output | Higher power output at higher RPMs | Lower power output at lower RPMs |

| Engine Noise | Generally quieter compared to diesel engines | Diesel engines tend to be noisier due to higher compression and combustion pressures |

| Thermal Efficiency | Thermal efficiency is low due to low compression ratio. It may be up to 25%. | Thermal efficiency is high due to high compression ratio. It may be up to 40%. |

| Engine Size | Usually smaller and lighter | Generally larger and heavier |

| Heating | Overheating trouble is more due to low thermal efficiency | Overheating trouble is less due to high thermal efficiency |

| Emissions | Emit higher levels of CO2 and other pollutants | Emit lower levels of CO2 but higher levels of particulate matter and NOx |

| Maintenance Costs | Generally lower maintenance costs | Higher maintenance costs due to more complex components |

| Initial Cost | Generally lower initial cost compared to diesel engines | Higher initial cost due to stronger construction and more complex systems |

| Cold Start Performance | Generally better in cold weather conditions | May require glow plugs or other systems for cold starts |

| Engine life | Shorter lifespan compared to diesel engines | Longer lifespan due to stronger construction and lower RPMs |

| Performance at High Altitudes | Generally better performance at higher altitudes | Slightly reduced performance at higher altitudes |

| Engine Response | Faster throttle response | Slightly slower throttle response |

| Availability of Fuel | Widely available in most regions | Less widely available compared to petrol |

| Environmental Impact | Emit higher greenhouse gas emissions | Emit lower greenhouse gas emissions but higher particulate emissions |

| Fuel Economy under Load | Generally less efficient under heavy loads | More efficient under heavy loads |

| Suitable Applications | Urban driving, sports cars, smaller vehicles | Heavy-duty vehicles, long-distance driving, towing |

| Turbocharging / Supercharging | Commonly used for performance enhancement | Less common due to already high torque at low RPMs |

“MechView: Unveiling Mechanical Engineering, Simply Explained!”