Clutch

A clutch is a mechanical device used in vehicles with manual transmissions to engage and disengage the power transmission between the engine and the gearbox. It is located between the engine and gearbox. The various types of clutches used in automobile depends upon the type and use of vehicle.

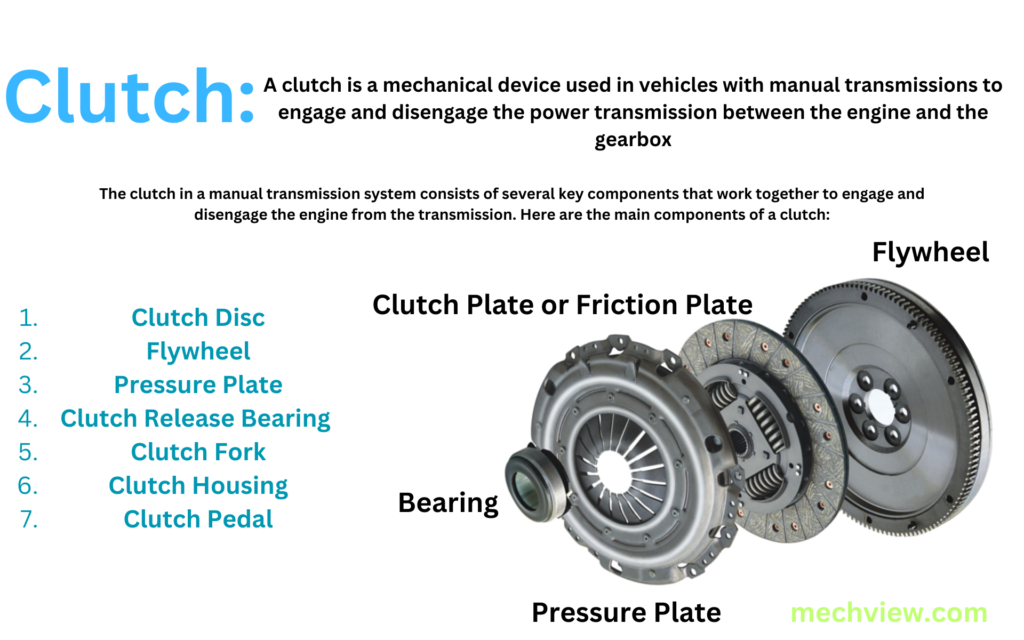

The clutch in a manual transmission system consists of several key components that work together to engage and disengage the engine from the transmission. Here are the main components of a clutch:

- Clutch Disc: Also known as the friction disc, this component is usually made of a high-friction material like organic, ceramic, or carbon fiber. It’s sandwiched between the flywheel and pressure plate and transfers power from the engine to the gearbox when engaged.

- Flywheel: The flywheel is a heavy rotating disc attached to the engine’s crankshaft. It provides inertia and helps smooth out engine power delivery. The clutch disc is pressed against the flywheel when the clutch is engaged, transmitting power.

- Pressure Plate: The pressure plate applies force to the clutch disc, pressing it against the flywheel when the clutch pedal is released. It uses a diaphragm spring or coil springs to exert this pressure, ensuring a solid connection between the engine and transmission.

- Clutch Release Bearing: Also known as the throw-out bearing, this component facilitates the disengagement of the clutch when the pedal is depressed. It applies force to the pressure plate fingers, releasing the pressure on the clutch disc and allowing it to spin freely.

- Clutch Fork and Release Mechanism: The clutch fork is a lever that moves the clutch release bearing when the clutch pedal is pressed. It’s connected to the clutch pedal via a linkage or hydraulic system, translating pedal movement into action on the clutch assembly.

- Clutch Housing: This is the housing that contains the clutch assembly and connects it to the transmission input shaft. It also provides protection and support for the clutch components.

- Clutch Pedal and Linkage: The clutch pedal is located inside the vehicle and is pressed by the driver to engage or disengage the clutch. It’s connected to the clutch fork via a mechanical linkage or hydraulic system, allowing the driver to control the clutch operation.

Functions of Clutch:

1. Engagement and Disengagement: The primary function of a clutch is to connect and disconnect the engine from the gearbox. When you press the clutch pedal, the clutch disengages, allowing you to change gears without affecting the engine’s rotation. Releasing the clutch pedal re-engages the clutch, transferring power from the engine to the gearbox.

2. Smooth Gear Changes: Clutches enable smooth gear changes by temporarily disconnecting the engine from the gearbox. This allows the driver to shift gears without causing excessive wear on the transmission components or stalling the engine.

3. Controlled Power Transfer: Clutches help in controlling the transfer of power from the engine to the wheels. By engaging or disengaging the clutch, the driver can control the speed and torque applied to the wheels, especially during acceleration or deceleration.

4. Protecting Transmission Components: Clutches play a crucial role in protecting the transmission components, such as gears and shafts. By disconnecting the engine during gear changes or when the vehicle is stationary, clutches prevent unnecessary wear and damage to these components.

5. Start-Up Assistance: In vehicles with manual transmissions, the clutch allows for smooth engine starting. By disengaging the engine from the gearbox, the clutch prevents the transmission from engaging until the driver is ready to move the vehicle.

6. It allows to change of gears when the vehicle is in motion.

7. It permits the stop of the vehicle without engine cut off.

Types of Clutches

1. Single Plate Friction Clutch: This type of clutch consists of a single friction plate sandwiched between the flywheel and pressure plate. When engaged, the friction plate connects the engine to the gearbox. Single plate friction clutches are commonly used in small vehicles, motorcycles, and light-duty applications due to their simplicity and compact design.

2. Multiple Plate Friction Clutch: In contrast to the single plate clutch, the multiple plate friction clutch has several friction plates interleaved with steel plates. This design provides higher torque capacity and better heat dissipation, making it suitable for heavy-duty vehicles, trucks, and performance-oriented applications where increased durability and power transfer are required.

3. Centrifugal Clutch: This type of clutch operates based on centrifugal force. It consists of weighted arms or shoes that are pushed outward by centrifugal force as the engine speed increases. This action engages the clutch, connecting the engine to the transmission. Centrifugal clutches are commonly found in small engines, such as lawn mowers, go-karts, and some motorcycles, where automatic engagement is desirable based on engine speed.

4. Semi-Centrifugal Clutch: Similar to the centrifugal clutch, a semi-centrifugal clutch uses centrifugal force for engagement. However, it also incorporates a manual engagement mechanism, allowing the driver to control clutch engagement manually. This type of clutch is often used in off-road vehicles, ATVs, and certain industrial applications that require a balance between automatic and manual clutch operation.

5. Cone Clutch: A cone clutch operates using conical friction surfaces. When the clutch is engaged, the conical surfaces mate together, transmitting power from the engine to the gearbox. Cone clutches are commonly used in heavy machinery, industrial equipment, and some racing vehicles due to their ability to handle high torque loads and provide smooth engagement.

6. Hydraulic Clutch: A hydraulic clutch uses hydraulic fluid pressure to engage and disengage the clutch mechanism. It typically consists of a master cylinder, slave cylinder, and hydraulic lines. Hydraulic clutches offer smoother and more consistent operation compared to mechanical linkages, making them popular in modern cars, trucks, and motorcycles, especially those with manual transmissions.

“MechView: Unveiling Mechanical Engineering, Simply Explained!”