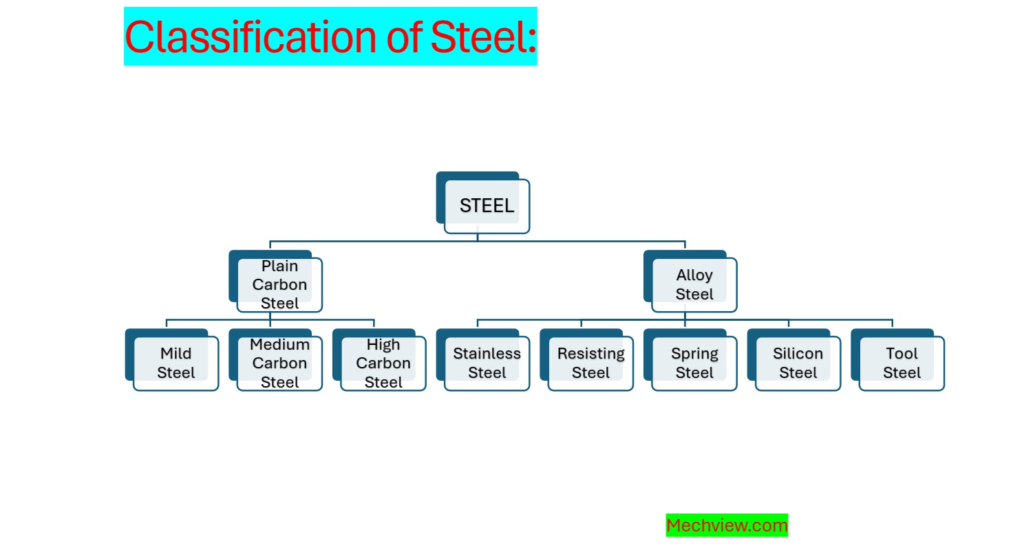

Definition of Steel:

Steel is an alloy of iron and carbon, typically containing less than 2% carbon by weight, along with other elements such as manganese, chromium, nickel, or molybdenum. It is characterized by its strength, ductility, and versatility, making it a widely used material in construction, manufacturing, and various industries. These Steels are called plain carbon steel because they own their property mainly due to the percentage of carbon present in them.

Classification of Plain Carbon Steel:

- Mild Steel or Low Carbon Steel: Mild steel, also known as low carbon steel, is a type of steel that contains a relatively low amount of carbon, typically around 0.01% to 0.3% by weight. It is one of the most common types of steel used in various applications due to its affordability, ease of fabrication, and versatility.

Properties of Mild Steel:

- Strength: Mild steel has moderate tensile and yield strength, making it suitable for structural applications where strength is required but not at extremely high levels.

- Ductility: It exhibits good ductility, allowing it to be easily formed, bent, and shaped without fracturing, making it ideal for fabrication processes.

- Machinability: Mild steel is easy to machine and work with, allowing for efficient cutting, drilling, welding, and shaping operations.

- Weldability: It has excellent weldability, making it suitable for welding and joining processes without compromising its structural integrity.

- Corrosion Resistance: While mild steel is susceptible to corrosion in certain environments, it can be protected through surface coatings, painting, or galvanization.

- Cost-Effective: Mild steel is affordable and readily available, making it a cost-effective choice for a wide range of applications.

- Versatility: It is used in various industries, including construction, automotive, manufacturing, infrastructure, and household appliances, due to its versatility and range of properties.

- Recyclability: Mild steel is recyclable, contributing to sustainable practices and environmental benefits in material usage.

Applications: Mild steel is used in construction, automotive parts, manufacturing, structural engineering, household appliances, furniture, piping, infrastructure, storage tanks, and DIY projects due to its strength, ductility, weldability, and affordability.

2. Medium Carbon Steel: Medium carbon steel is a type of steel alloy that contains a higher percentage of carbon compared to low carbon steel but less than high carbon steel, typically ranging from 0.3% to 0.8% carbon by weight. This composition gives medium carbon steel enhanced strength and hardness while maintaining some level of ductility.

Properties of Medium Carbon Steel:

- Strength: Medium carbon steel exhibits higher strength than low carbon steel, making it suitable for applications requiring more structural integrity and load-bearing capacity.

- Hardness: It has good hardness due to its increased carbon content, making it suitable for parts that need to withstand wear, abrasion, and impact.

- Ductility: While not as ductile as low carbon steel, medium carbon steel still retains some level of ductility, allowing for moderate deformation and shaping during fabrication.

- Machinability: It has fair machinability, requiring appropriate tools and machining techniques for cutting, drilling, and shaping operations.

- Weldability: Medium carbon steel can be welded using suitable welding methods, although preheating and post-weld heat treatment may be necessary to avoid brittleness and maintain strength.

- Toughness: It possesses good toughness, enabling it to absorb energy and resist fracture under impact or sudden loads.

- Corrosion Resistance: Medium carbon steel may exhibit improved corrosion resistance compared to high carbon steel, especially with proper surface treatments or coatings.

Applications: Medium carbon steel is commonly used in applications such as automotive components, machinery parts, gears, axles, shafts, structural steel, and tools where a balance between strength, hardness, and ductility is required.

3. High Carbon Steel: High carbon steel is a type of steel alloy that contains a higher percentage of carbon compared to medium or low carbon steels, typically ranging from 0.8% to 1.5% carbon by weight. This increased carbon content contributes to its exceptional hardness, strength, and wear resistance.

Properties of High Carbon Steel:

- Exceptional Hardness: High carbon steel is known for its exceptional hardness, making it suitable for applications requiring cutting, drilling, and shaping tools that can retain sharp edges.

- High Strength: It exhibits high tensile and yield strength, providing excellent structural integrity and load-bearing capacity in applications such as springs and high-stress components.

- Low Ductility: Compared to low and medium carbon steels, high carbon steel has lower ductility, making it more brittle and less suitable for applications requiring extensive deformation or bending.

- Wear Resistance: It offers excellent wear resistance, making it suitable for applications subjected to abrasive wear, such as cutting tools, knives, blades, and machine parts.

- Machinability: High carbon steel can be challenging to machine due to its hardness and brittleness, requiring specialized tools and machining techniques.

- Heat Treatment: It responds well to heat treatment processes such as quenching and tempering, allowing for customization of its mechanical properties based on the application requirements.

- Corrosion Resistance: High carbon steel is more susceptible to corrosion compared to low carbon steels, and proper surface treatments or coatings are often necessary to improve its corrosion resistance.

Applications: High carbon steel finds applications in manufacturing cutting tools, springs, knives, saw blades, chisels, axes, gears, and other high-stress components where hardness, strength, and wear resistance are critical.

Alloy Steel:

Alloy steel is a type of steel that contains additional alloying elements besides carbon, such as manganese, chromium, nickel, molybdenum, vanadium, or silicon. These alloying elements are added to enhance specific properties of the steel, such as strength, hardness, toughness, corrosion resistance, and wear resistance.

The purpose of alloy steel varies depending on the specific alloying elements used and the intended application. Some common purposes and benefits of alloy steel include:

- Improved Strength: Alloy steel can have higher tensile and yield strength compared to carbon steel, making it suitable for applications requiring enhanced structural integrity and load-bearing capacity.

- Enhanced Hardness: Alloying elements like chromium and molybdenum contribute to increased hardness, making alloy steel suitable for cutting tools, wear-resistant components, and high-wear applications.

- Increased Toughness: Certain alloying elements improve the toughness and impact resistance of alloy steel, making it suitable for applications subjected to dynamic loads, shock, and vibration.

- Corrosion Resistance: Alloy steel can be engineered to have improved corrosion resistance, making it suitable for environments with exposure to moisture, chemicals, and corrosive substances.

- Heat Resistance: Some alloy steels exhibit excellent heat resistance, allowing them to maintain their mechanical properties at high temperatures, making them suitable for applications in high-temperature environments such as engines, turbines, and exhaust systems.

- Wear Resistance: Alloy steel with specific alloying elements such as manganese, chromium, or vanadium can have enhanced wear resistance, making it suitable for wear-prone components like gears, bearings, and cutting tools.

- Versatility: Alloy steel’s versatility allows it to be tailored to meet specific application requirements, offering a wide range of properties and performance characteristics.

- Cost-Effectiveness: Despite its enhanced properties, alloy steel can often be more cost-effective than other materials with similar performance, making it a preferred choice in various industries.

“MechView: Unveiling Mechanical Engineering, Simply Explained”